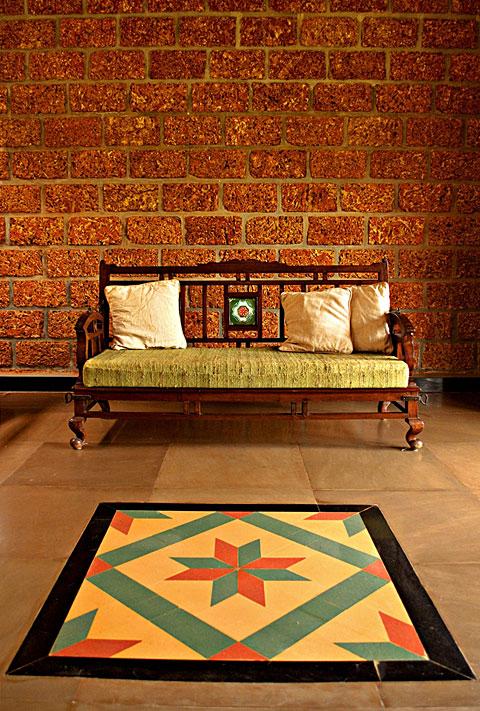

Laterite is well known as a building material for more than thousands of years. When moist, laterite can be cut into different shapes and sizes . Once mined and exposed to air it gets hardened and become resistant to atmospheric conditions. Laterite is a 100 percentage natural Eco-friendly product and that quality makes it the most preferred construction material. The lovely color and texture along with its strength and physically resistant nature makes it compatible for both interior and exterior architecture . This natural stone possesses a unique rust colour and texture . It is a zero finish material which can be used as a building block (load bearing) directly as well as for wall cladding.

Laterite and Stone work

Laterite Cladding